|

| November 08, 2022 | Volume 18 Issue 42 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

SPE Automotive Innovation Awards winners announced

The Automotive Division of the Society of Plastics Engineers (SPE) announced the winners for its 51st annual Automotive Innovation Awards Competition at an awards gala held Nov. 2 at the Burton Manor in Livonia, MI -- the oldest and largest recognition event (established in 1970) in the automotive and plastics industries. The Chassis/Hardware category winner was also this year's Grand Award winner, selected from the winners of each of the 10 categories by a panel of blue-ribbon judges who are industry experts.

Dozens of teams made up of OEMs, tier suppliers, and polymer producers submitted nominations to SPE's Automotive Innovation Awards Program describing their part, system, or complete vehicle and why their work merits the claim as the Year's Most Innovative Use of Plastics. The annual event draws approximately 700 OEM engineers, automotive and plastics industry executives, and media. Funds raised from the event are used to support SPE educational programs including technical seminars and conferences, which help educate and secure the role of plastics in the advancement of the automobile.

This year's program was made possible with the support from the following sponsors: Celanese, SABIC, DuPont, DSM, The American Chemistry Council - Plastics Division, Ascend Performance Materials, BASF, Covestro, INEOS Styrolution, Inteva Products, LyondellBasell, Fast Radius, and Van Norman Molding.

This year's award winners are:

GRAND AWARD & CATEGORY WINNER: Chassis/Hardware

Tension Leaf Spring

- OEM Make & Model: 2022 General Motors Co. Chevrolet Silverado & GMC Sierra

- Tier Supplier/Processor: Mubea (Muhr und Bender KG)

- Material Supplier/Toolmaker: Multiple/Mubea (Muhr und Bender KG)

- Material/Process: Epoxy/Prepreg Layup and Compression Molding

The first all-composite leaf spring for light truck programs reduces mass up to 75% vs. all-steel and 58% vs. hybrid steel/composite solutions while doubling durability, eliminating corrosion, improving ride comfort, lowering NVH (noise, vibration, and harshness), and increasing payload. Fiberglass-reinforced epoxy prepreg is used to form a single leaf with a progressive spring rate that eliminates the shackle, shackle bushing, and helper leaves yet passes all OEM test requirements.

--------------

CATEGORY WINNER: Additive Manufacturing

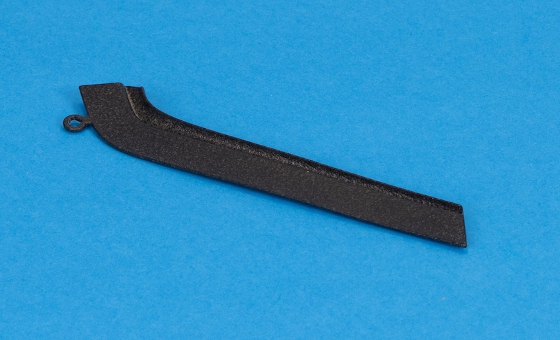

Spoiler Closeout Seal

- OEM Make & Model: 2022 General Motors Co. Chevrolet Tahoe, Chevrolet Suburban, Cadillac Escalade, GMC Yukon

- Tier Supplier/Processor: HP Inc. & AMT Ltd./GKN Additive (Forecast 3D)

- Material Supplier/Toolmaker: BASF Corp./GKN Additive (Forecast 3D)

- Material/Process: BASF SE Ultrasint TPU01 TPU/HP Multi Jet Fusion 5200 Series

The powder-bed fusion process was used to source, print, process, and install 60,000 TPU spoiler closeout seals to meet 10 weeks of production as a bridge solution while hard tooling was being produced. Innovative vapor polishing and drying processes cleared a bottleneck, halved production time, and were used to finish parts, eliminating the need for post-print dyeing. The seals close out gaps on left and right sides of rear spoiler, improving finish and fuel efficiency.

--------------

CATEGORY WINNER: Aftermarket & Limited Edition/Specialty Vehicles

Carbon Fiber C-Brace

- OEM Make & Model: 2022 Ford Motor Co. Ford Bronco Raptor

- Tier Supplier/Processor: Montaplast of North America

- Material Supplier/Toolmaker: BASF Corp./Commercial Tool Group

- Material/Process: Ultramid B3WC4 HP CF & GR PA6/Injection Molding

This customer-visible, Class A C-brace was designed to meet off-road desert durability requirements for convertible versions of the vehicle while boosting torsional stiffness 40% to improve handling and NVH. Weight was reduced 55% vs. aluminum and 85% vs. steel by adopting a sandwich composite approach. Upper and lower shells were injection molded in 35% GR PA6, while a core was injection molded in 20% CF-PA6. Components were then bonded with a newly formulated methacrylate adhesive.

--------------

CATEGORY WINNER: Body Exterior

Panoramic Sunroof Frame

- OEM Make & Model: 2022 Hyundai Motor Group Kia Sorento

- Tier Supplier: Inalfa Roof Systems Korea

- Material Supplier: GS Caltex Corp.

- Material/Process: Hiprene ALG14BF PA6/Injection Molding

Several novel technologies contributed to this large injection-molded LFT-PA6 panoramic sunroof frame. First, flat rather than round glass fibers provided higher dimensional stability and reduced warpage. Second, the twist pultrusion was used to produce LFT pellets whose fiber length exceeds the length of the pellets, again contributing to mechanical improvements. Weight was reduced 51%, and part count dropped from 33 to 4 vs. a steel frame. Versus carbon fiber-reinforced LFT, torsional rigidity was 13% higher, and breaking force 25% better at 24% lower cost.

--------------

CATEGORY WINNER: Body Interior

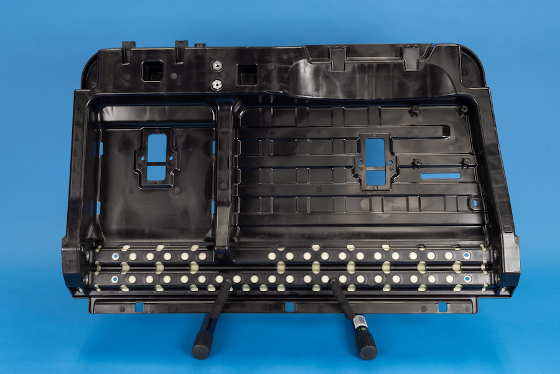

2nd-Row Seat Backs & Cushions

- OEM Make & Model: 2022 Toyota Motor Corp. Toyota Tundra

- Tier Supplier/Processor: Flex-N-Gate Corp. & Adient/Flex-N-Gate Corp. & L&L Products

- Material Supplier/Toolmaker: BASF Corp./SyBridge Technologies

- Material/Process: Ultramid B3ZG7 35% GR-PA6 & Elastocoat 74850 80% GR-PUR PA6 & PU/Pultrusion and Injection Overmolding

This composite seat structure combines a pultruded continuous fiberglass-reinforced PUR reinforcement beam that is injection overmolded with short-glass/PA6 to form the seat frame geometry. By replacing a 60-piece high-strength steel frame structure with a 4-piece molded composite structure, significant crash performance improvements were achieved, while both cost and mass targets of 20% reduction were met. Additionally, over 100 welds at 16 weld stations were eliminated, significantly improving quality control, and under-seat storage that wasn't possible with the previous solution was added.

--------------

CATEGORY WINNER: Electric & Autonomous Vehicle Systems

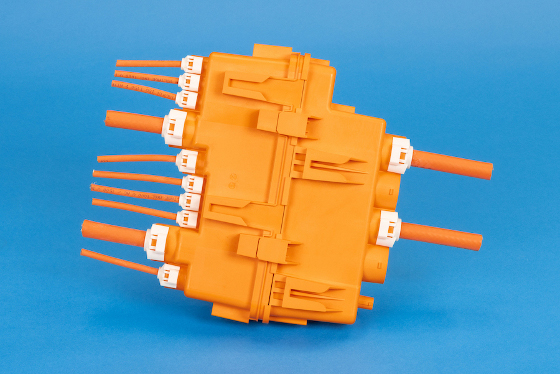

High-Voltage Power Distribution System

- OEM Make & Model: 2022 Ford F-150 Lightning

- Tier Supplier/Processor: Aptiv PLC/Yazaki North America, Inc.

- Material Supplier: DuPont de Nemours, Inc.

- Material /Process: Crastin FR684 & HR5339 PBT/Injection Molding, Silicone Overmolding

This customizable, shielded high-voltage power distribution system permits 7 sets of subassemblies and up to 64 possible configurations from a single tool, providing both flexibility and scalability for future programs. Three different materials are used: a flame-retardant 25% GR-PBT forms the internal assembly and terminal blocks, and a silicone seal is overmolded directly onto a 30% GR-PBT cover. A unique shielding system uses stamped connection interfaces that reduce mass by two-thirds vs. cast products while maintaining electromagnetic shielding.

--------------

CATEGORY WINNER: Materials

Thermoplastic BEV Thermal Management Solution

- OEM Make & Model: 2023 General Motors Co. Cadillac Lyriq

- Tier Supplier/Processor: Cooper Standard Automotive, Inc.

- Material Supplier/Toolmaker: DuPont de Nemours, Inc., Dow Chemical Co., LyondellBasell Industries/Cooper Standard Automotive, Inc.

- Material/Process: PA6/12, PA66 & PP/Extrusion, Molding, Forming, and Automated Assembly

Two developments provide a lightweight, thermoplastic solution for EV thermal management systems. PlastiCool 2000 multilayer tubing for glycol applications to 120 C provides excellent chemical resistance, 25% better permeation resistance, and 60% lower weight than EPDM, and is available in smooth, convoluted, round, and non-round configurations. Ergo-Lock+ modular VDA connectors are flexible, offer visual and scannable latch verification, and reduce insertion forces by greater than 30%. The system's modularity permits hundreds of connector configurations to be produced from a standard set of molded subcomponents at lower total cost.

--------------

CATEGORY WINNER: Powertrain

High-Pressure Oil Cooler Gasket Seal

- OEM Make & Model: 2022 General Motors Co. Chevrolet Silverado & GMC Sierra

- Tier Supplier/Processor: Uchiyama Marketing & Development America LLC

- Material Supplier/Toolmaker: Uchiyama Marketing & Development America LLC & DuPont de Nemours, Inc./Uchiyama Marketing & Development America LLC

- Material /Process: UMC V7401 Ethylene Acrylic Elastomeric Plastic/Injection Molding

Oil cooler gaskets are small parts with important sealing functions between oil coolers and oil pumps in demanding engine environments. To eliminate leaks seen with fluorocarbon seals during temperature cycling, a new ethylene acrylic TPV was developed. It offers superior low-temperature sealing and maintains good compression set and controlled oil swelling from -40 to 150 C and 14 bars oil pressure. Gasket height also was increased to provide higher contact pressure and better sealing. Costs were reduced 66%, and sustainability was increased since the thermoplastic material is recyclable.

--------------

CATEGORY WINNER: Process/Assembly/Enabling Technologies

Direct Exposure Laser Welding

- OEM Make & Model: 2022 General Motors Co. Chevrolet Blazer

- Tier Supplier/Processor: Magna Lighting

- Material Supplier/Toolmaker: Various/SPM Automation

- Material/Process: Makrolon LED 2245 000000 PC/Injection Molding, Laser Welding

Hot-plate welding was replaced with a new process called direct exposure laser welding to meet customer styling requirements for the light guides. Scanning lasers replace heated tools and can weld opaque lens borders without the need for more costly laser-transparent materials. Clearance between internal components and weld ribs was reduced and ribs can be heated very precisely. The current design's complex geometries would not have been possible with traditional welding processes. Additionally, scrap was reduced 40 to 50% and energy usage by 85 to 95%.

--------------

CATEGORY WINNER: Sustainability

Reclaimed TPO/Foam System

- OEM Make & Model: 2020 General Motors Co. Chevrolet Silverado & GMC Sierra

- Tier Supplier/Processor: Inteva Products, LLC

- Material Supplier: Inteva Products, LLC

- Material /Process: Inteather TGTPO ECO TPO/Extrusion and Repellitizing; Co-Extrusion of TPO Sheets; Vacuum Forming & Injection Graining; Press Lamination; and Assembly

Thanks to a patented recycling process, PIR bilaminate scrap comprised of TPO skins attached to cross-linked olefin foam is given new life in the same interior trim applications without sacrificing quality or performance. An additive package eliminates/binds/deactivates reactive residuals and trapped gases from foam. Just on this program, 680,389 kg of TPO resin is reclaimed annually, reducing landfilled scrap 93%, replacing 50% of prime TPO, and lowering CO2 emissions and energy usage 48% each.

--------------

CATEGORY WINNER: VETA (VEHICLE ENGINEERING TEAM AWARD)

The all-electric 2023 Cadillac LYRIQ and a team from General Motors Co. (GM, Detroit) and its suppliers that developed the midsize sport utility vehicle (SUV) have been named the winners of this year's Vehicle Engineering Team Award (VETA). The VETA award was created by SPE in 2004 to recognize the technical achievements of entire teams -- comprised of automotive designers and engineers, tier integrators, materials suppliers, toolmakers, and others -- whose work in research, design, engineering, and manufacturing has led to significant integration of polymeric materials on notable vehicles. The vehicle features numerous plastic and composite innovations, many of which were nominated in other categories of SPE's Automotive Innovation Awards Competition, including the following:

- Aftermarket & Limited Edition/Specialty Vehicles Finalist: Electric Vehicle Supply Equipment (EVSE) Charging Accessory

- Aftermarket & Limited Edition/Specialty Vehicles Nomination: Ultium Battery Charger

- Body Exterior Finalist: Flow-Through Spoiler

- Body Exterior Nomination: Front Headlamp System

- Body Exterior Nomination: Rear Body-Side Taillamp System

- Body Exterior Finalist: Front Enclosed Illuminated Grille

- Body Interior Nomination: High-Gloss Piano Black Molded-in-Color (MIC)

- Electric & Autonomous Vehicle Systems Nomination: Connection Ring for EV Motors

- Electric & Autonomous Vehicle Systems Finalist: High-Damping AC Compressor Bracket

- Materials Finalist: Dual Cordset EV Charger Lens

- Materials Finalist: Thermal Management Tube & Connector Solution

- Materials Nomination: Center Frame Panel

- Process/Assembly/Enabling Technology Nomination: Elastic Averaging Vehicle Attachment

- Sustainability Nomination: Recycled Resin Blow Molded Ducts

--------------

CATEGORY WINNER: HALL OF FAME AWARD

The first Mold In Color (MIC) weatherable grille, used on the 1987 Volkswagen Golf, has been named the 2022 Hall of Fame Winner. The industry's first MIC weatherable grille, made possible with Luran S® ASA from INEOS STYROLUTION (pre-colored plastic resins used in the plastic injection-molding process so the molded part emerges in a specific color and finish), proved to be a game changer for vehicle front grilles by providing a weatherable, paint-free exterior surface. To be considered for a Hall of Fame Award, an automotive plastic or composite component must have been in continuous service in some form for at least 15 years and broadly adopted in the automotive industry. This application certainly qualifies, as MIC grilles have become the industry standard used by every major OEM for front grilles, replacing traditionally painted materials on over 300 million exterior parts including grilles, mirrors, pillars, spoilers, fog bezels, and more.

Further technology now being developed around MIC ASA includes radar detection covers, lidar equipment, and CHMSL (Center High-Mounted Stop Lamp) bezels. The automotive market for MIC ASA has now grown to over 100 million lb globally.

The companies involved in developing the first MIC weatherable grille application include: OEM - Volkswagen Group; Molder/Processor - Volkswagen Group; and Material Supplier - INEOS STYROLUTION. Representatives from these companies accepted the SPE Automotive Hall of Fame Award on behalf of the original team that worked to develop the technology.

--------------

CATEGORY WINNER: LIFETIME ACHIEVEMENT AWARD

Probir Guha.

Over his almost 50-year career, Guha key innovations in the field reflected by his many global patents (179 patents issued and pending as of June 19, 2022); participated in industry technical conferences presenting several papers and holding committee leadership positions; was recognized with an industry award for innovation, research, and advancements with the 2019 Pioneer Award by The American Composites Manufacturers Association (ACMA); and has edited a book where he coordinated the efforts of industry and academic experts to share concepts of how to further the composites industry.

Guha recently formed a technology consulting company, Composites Innovations Inc., bringing the adoption of lightweight materials across multiple applications focusing on sustainability and recyclability, continuous hybrid fibers, smart composite technologies, and artificial intelligence in products for continuous improvement.

For more information about the SPE Automotive Division, got to speautomotive.com.

For more information on the Society of Plastics Engineers, go to www.4spe.org.

Source: Society of Plastics Engineers (SPE)

Published November 2022

Rate this article

View our terms of use and privacy policy